MANAGEMENT OF PRODUCTION ORDERS

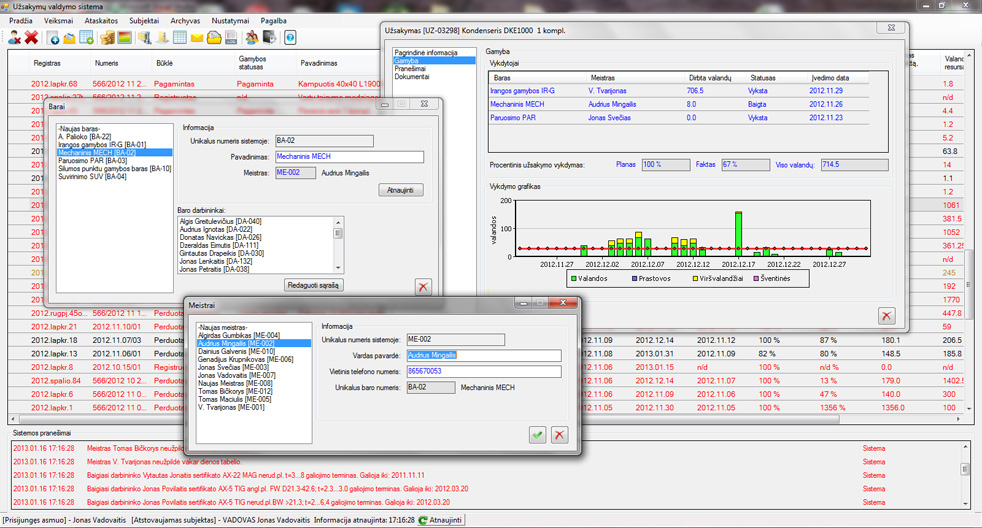

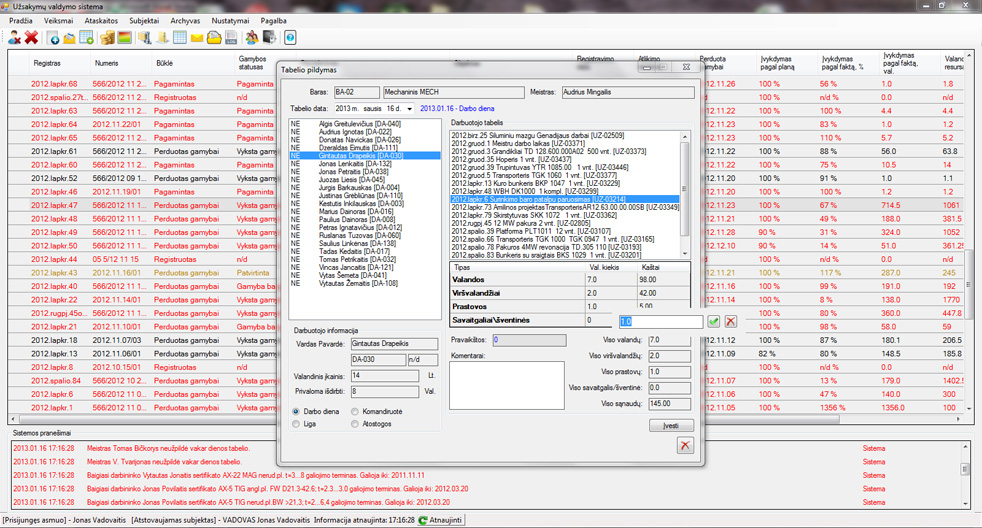

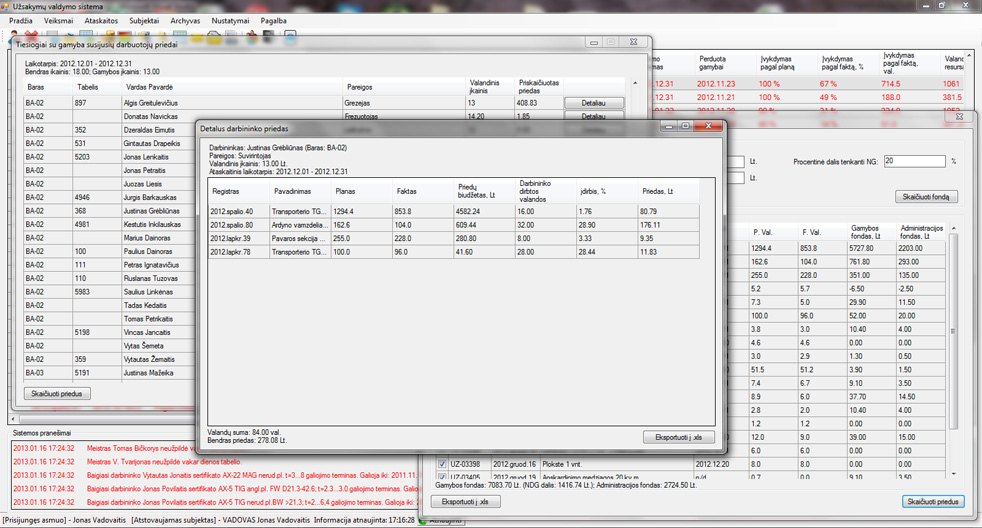

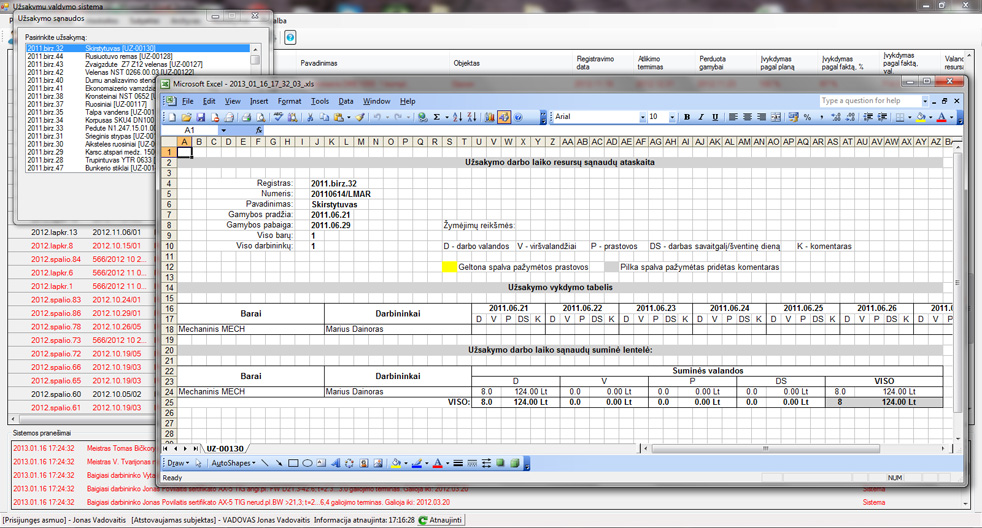

Implementation of partially automated order management system: from the order acceptance stage up to the final reply to the client via e. mail stage. Participants included in the system: coordinating foreman, production foreman, site foreman, accountant and the division manager which approves the production act and specifies the final cost of the order. Afterwards, the above mentioned data is passed to the coordinating foreman who continues the further communication with the client.

BENEFITS OF THE PROJECT:

• System terminals enable easy access to the ongoing order information, streamlined supervision of ongoing order progress

• Clearly defined responsibility of separate chains

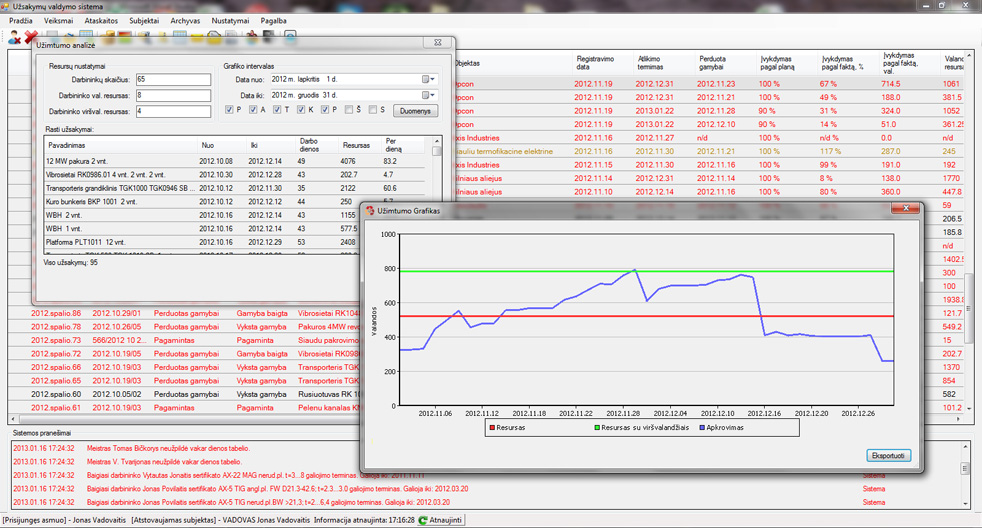

• Automated analysis of the production resource cost (reduction of human resources)

• Recording employee time sheets and actual work costs ensures the supervision of ongoing orders

• Automated notification system for the client

• All of the information related to orders (designs, acts, client data, etc.) is stored on the system servers and is easily accessible via system terminals

Task

Streamline order accounting tasks, implement effective supervision for the ongoing orders, perform automated analysis of the production resource usage, methodically gather and store information related to the orders and also streamline the determination of responsibility for separate order processing chains.